Maximizing efficiency and precision in diamond wire cutting requires more than just high-quality equipment—it also depends on proper setup, optimized parameters, and regular maintenance. Many manufacturers struggle with material waste, inconsistent cuts, and machine downtime simply because they haven’t fine-tuned their cutting process.

In this step-by-step guide, we break down how to optimize your diamond wire cutting process for maximum efficiency, minimal waste, and superior cutting quality.

🎥 Watch our video tutorial

Step 1: Selecting the Right Cutting Parameters

Different materials require specific cutting parameters to achieve the best results. Incorrect settings can lead to material cracking, wire breakage, and uneven cuts.

Optimized Parameters for Different Materials

| Material | Recommended Wire Speed (m/s) | Feed Rate (mm/min) | Coolant Use |

|---|---|---|---|

| Sapphire | 25 – 30 | 1.0 – 2.5 | oil |

| Quartz | 20 – 25 | 1.5 – 3.0 | oil |

| Silicon Carbide (SiC) | 30 – 35 | 0.5 – 2.0 | oil |

| Boron Nitride | 20 – 25 | 1.0 – 2.5 | oil |

| Piezoelectric Ceramics | 25 – 30 | 1.2 – 2.8 | oil |

✅ Tip: Always start with the recommended range and fine-tune based on the material type and thickness. Adjust the feed rate if excessive force is required or if you notice surface imperfections.

Step 2: Ensuring Proper Wire Tension & Alignment

Incorrect wire tension leads to inconsistent cutting quality, premature wire wear, and breakage.

How to Optimize Wire Tension:

🔹 Keep tension stable between 100-110 N (Newtons) to prevent slack.

🔹 Use auto-tensioning systems (available in VIMFUN machines) to adjust in real-time.

✅ Tip: For hard and brittle materials like SiC, higher tension is needed to maintain straight-line precision.

Step 3: Adjusting the Cutting Speed for Maximum Efficiency

Many manufacturers set cutting speeds too low or too high, leading to inefficiency or material damage.

Speed vs. Material Hardness:

✔ Harder materials (SiC, Sapphire): Use slower feed rates to prevent cracks.

✔ Softer materials (Quartz, BN): Increase cutting speed for faster throughput.

✔ Composite materials: Reduce speed to prevent delamination.

🔍 What happens if speed is too high?

❌ Wire vibrations increase → Uneven cuts

❌ More heat is generated → Potential material damage

❌ Excessive stress → Faster wire wear

✅ Tip: Monitor the wire performance throughout the cut and adjust speed dynamically if necessary.

Step 4: Using the Right Coolant & Lubrication System

Efficient cooling is essential to prevent heat-induced defects and extend the lifespan of the diamond wire.

Coolant Best Practices:

✔ Use high-purity coolant to prevent contamination.

✔ Maintain a steady flow to remove cutting debris.

✔ Adjust the pressure based on material type (higher for SiC, lower for piezoelectric ceramics).

🎥 See our real-time coolant application process in the video demonstration!

✅ Tip: Regularly clean the coolant nozzles to prevent clogging and inconsistent flow.

Step 5: Preventing Material Waste & Maximizing Yield

One of the biggest concerns in precision cutting is material utilization. Our optimization techniques can help reduce waste by up to 35%.

How to Reduce Waste:

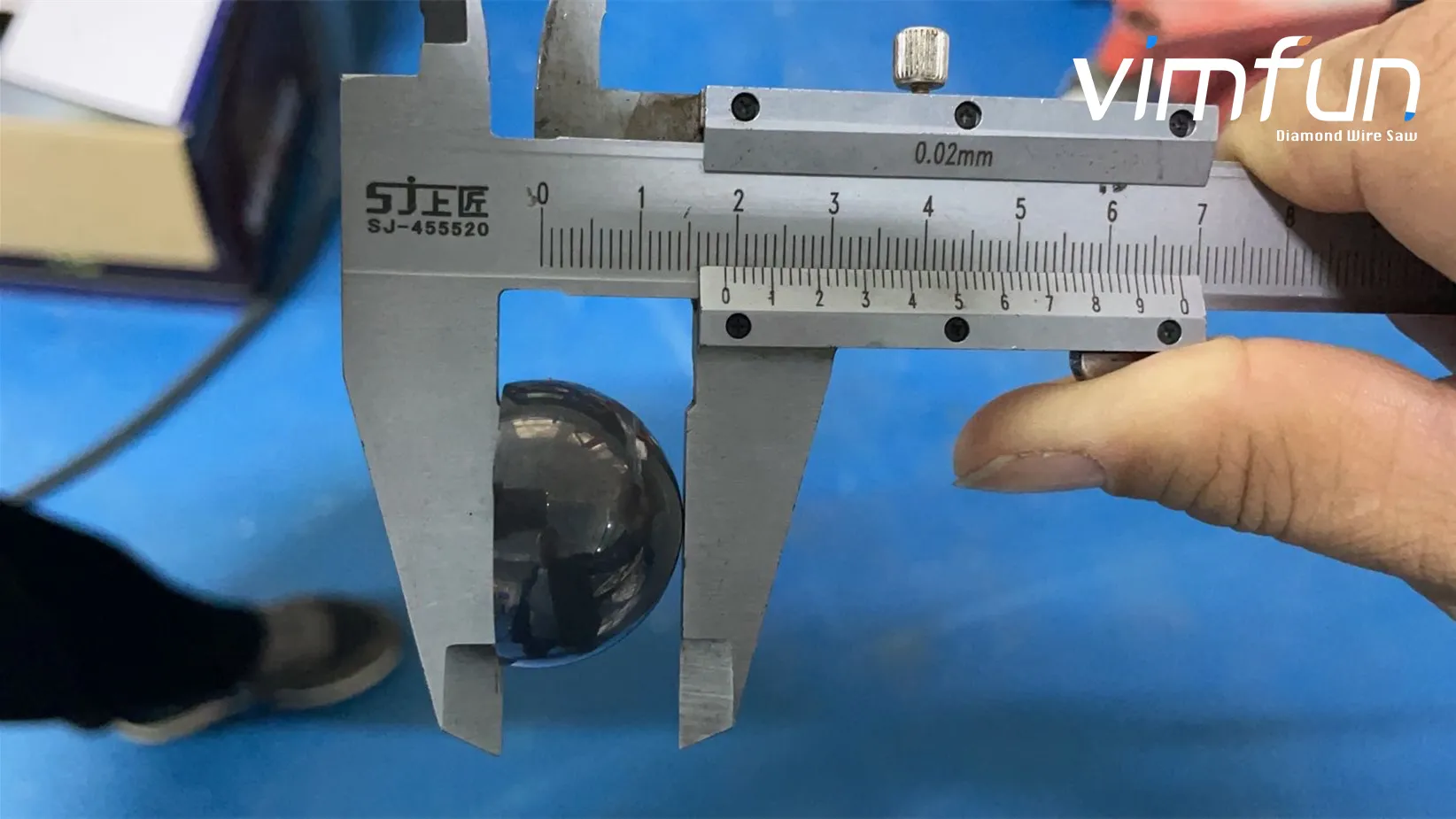

🔹 Use a narrower kerf – VIMFUN’s diamond wire allows for a 0.4 mm – 0.45 mm kerf, reducing waste.

🔹 Optimize nesting patterns – Arrange cuts to maximize material yield.

🔹 Implement real-time process monitoring – VIMFUN machines adjust automatically to minimize deviations.

Step 6: Machine Maintenance for Consistent Performance

Even the best cutting machines need regular maintenance to ensure long-term performance.

Daily Maintenance Checklist:

✔ Check wire tension before every cutting session.

✔ Inspect the wire for wear – Replace if diamond coating is visibly eroded.

✔ Clean the coolant system and remove any debris buildup.

✅ Tip: Schedule preventive maintenance to avoid costly downtime.

Real-World Impact: How VIMFUN’s Optimization Process Helped a Manufacturer

One of our clients, a leading optics manufacturer, faced challenges with material waste and cutting inconsistencies when processing sapphire wafers. After implementing VIMFUN’s optimized cutting strategies, they saw:

📉 30% reduction in material waste – Lower kerf width and optimized cutting parameters.

⚡ 40% increase in production speed – Faster cutting without defects.

💰 25% savings in maintenance costs – AI-driven diagnostics reduced downtime.

One of their engineers shared:

“By fine-tuning our process with VIMFUN’s optimization guide, we improved our yield and lowered costs dramatically.”

Why Choose VIMFUN for Precision Cutting Optimization?

For industries requiring high-precision cutting, VIMFUN’s diamond wire cutting machines offer:

✔ Customizable Cutting Parameters: AI-driven adjustments for optimal performance.

✔ Advanced Wire Tensioning System: Reduces wire breakage & improves cut accuracy.

✔ Intelligent Process Monitoring: Tracks real-time cutting conditions for consistent quality.

✔ Industry-Specific Solutions: Optimized settings for semiconductors, optics, and ceramics.

✔ Automated Maintenance Alerts: Ensuring maximum machine uptime.

🔹 Whether you manufacture silicon carbide wafers, LED substrates, or aerospace components, VIMFUN’s cutting technology can help you achieve the best results.

Conclusion: Optimize Your Cutting Process for Maximum Efficiency

By following this step-by-step guide, manufacturers can:

✅ Increase cutting precision while reducing defects.

✅ Improve yield rates by minimizing material waste.

✅ Enhance machine lifespan through proper maintenance.

💡 Want expert guidance on optimizing your diamond wire cutting process? Contact VIMFUN today for a customized consultation and cutting strategy.