In modern manufacturing, cutting costs are a critical factor in controlling overall production expenses, especially when working with high-precision and high-value materials. As technology continues to evolve, diamond wire cutting equipment has become an essential tool for many industries, helping to reduce cutting costs and improve production efficiency. Today, we’re sharing a successful customer story that demonstrates how our diamond wire cutting equipment helped a company significantly lower their cutting costs and improve overall production efficiency.

Customer Background:

Our customer is a globally recognized optical glass manufacturer, specializing in the production of high-precision optical components used in various high-tech fields, such as lasers, microscopes, sensors, and more. Due to the high hardness of optical glass and the need for extreme cutting precision, the company had been facing challenges such as low cutting efficiency, high waste, and escalating costs.

The company previously relied on cutting saws and electrical discharge machining (EDM) to cut their materials. While these traditional methods worked well for most materials, they encountered several problems when cutting optical glass and other hard materials. Specifically, the cutting saw blades wore out quickly, leading to increased operational costs, while EDM, though precise, was slow and inefficient, making it unsuitable for their high-speed production needs.

Challenges and Requirements:

After discussing their challenges with our team, the customer outlined the following key requirements:

- Increase cutting efficiency and reduce production cycle time.

- Minimize waste generated during cutting and reduce material costs.

- Maintain high cutting precision to ensure the quality of the final product.

- Lower equipment maintenance costs and reduce downtime.

To meet these needs, we conducted a thorough analysis of their production processes and collaborated closely with our technical team. We then recommended our latest diamond wire cutting equipment, which we believed would be the ideal solution.

Solution:

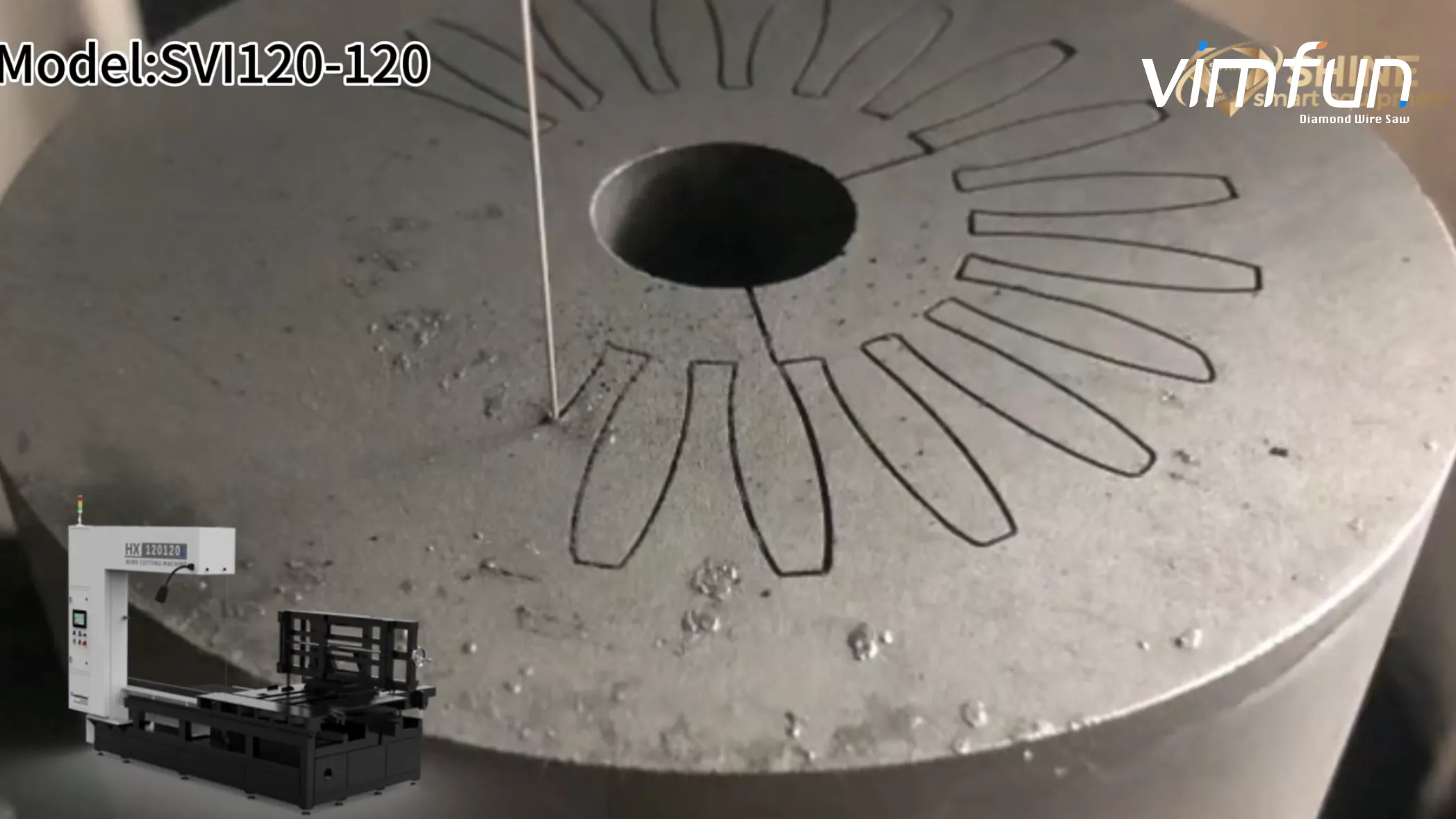

To address the customer’s challenges, we provided a tailored diamond wire cutting solution. The advantages of diamond wire cutting technology include:

- High Precision and Efficiency: Diamond wire cutting offers exceptional precision, ensuring smooth, flat edges on optical glass, which reduces the need for further processing.

- Reduced Waste: Compared to traditional cutting methods, diamond wire cutting generates significantly less waste, greatly reducing material consumption.

- Longer Lifespan: The wear resistance of diamond wire is far superior to that of saw blades, meaning it maintains high cutting performance for longer, reducing the need for frequent replacements and lowering maintenance costs.

- Lower Production Costs: Diamond wire cutting allows for faster processing times, enabling the customer to complete more cutting tasks in less time, thus reducing labor and time-related costs.

Throughout the implementation, our technical team provided comprehensive support to ensure smooth installation and offered training to the customer’s staff, enabling them to quickly learn how to operate the equipment.

Results and Benefits:

Since the introduction of our diamond wire cutting equipment, the customer has seen significant improvements in both cutting efficiency and precision. Here are the key outcomes:

- Cutting speed increased by 30%: Due to the high efficiency of diamond wire cutting, the customer was able to complete more cutting tasks in less time, significantly reducing production cycles.

- Waste reduced by 40%: By minimizing material waste, the customer not only saved on raw material costs but also lowered disposal expenses.

- Maintenance costs reduced by 50%: The durability of diamond wire means that it lasts several times longer than traditional saw blades, reducing equipment replacement and maintenance needs.

- Improved cutting precision: The customer reported that after switching to diamond wire cutting, the edges of the optical glass were much smoother, and the cutting precision was much higher, virtually eliminating any defects.

Customer Feedback:

The customer was highly satisfied with the performance of our equipment and provided the following feedback:

“Since we switched to diamond wire cutting equipment, our production efficiency has improved dramatically, and the cutting precision has been exceptional. We are particularly pleased with the significant reduction in material waste, which has not only cut costs but also enhanced our overall production efficiency. More importantly, the maintenance costs have been halved, and we no longer have to worry about frequent downtime and repairs. We are grateful for the excellent solution provided by your company and look forward to long-term cooperation!”

Conclusion:

This customer story highlights the outstanding performance of diamond wire cutting technology in the cutting of hard materials like optical glass. It demonstrates that diamond wire cutting not only delivers superior cutting precision and efficiency but also helps companies significantly reduce production costs. Through our technology and support, the customer has achieved substantial improvements in their manufacturing processes, resulting in better cost control and higher operational efficiency.

If your company is facing similar cutting challenges, our diamond wire cutting equipment could be the ideal solution for increasing efficiency and reducing cutting costs. Feel free to contact us to learn more and to customize a cutting solution that fits your business needs!

Closing Note: By sharing this customer story, we not only highlight the benefits of diamond wire cutting technology but also emphasize our commitment to providing exceptional service and support. This type of article helps build trust with potential clients and showcases our leadership in the industry.