In today’s world, sustainability and environmental impact are critical factors for businesses striving to stay competitive and responsible. This is especially true for industries involved in high-precision manufacturing, where material waste and energy consumption can significantly impact both costs and environmental footprints. As industries adopt more efficient technologies, our diamond wire cutting equipment stands out as a game-changer in reducing waste, improving resource utilization, and contributing to a greener manufacturing process.

In this article, we will explore how our diamond wire cutting machines help manufacturers achieve green manufacturing goals by minimizing waste generation, lowering energy consumption, and improving overall production efficiency.

The Challenge of Waste in Traditional Cutting Methods

In traditional cutting methods, such as saw cutting and EDM (electrical discharge machining), material waste is often high, especially when cutting hard and brittle materials like optical glass, sapphire, ceramics, and silicon carbide. These methods not only generate a large amount of material scrap but also require significant energy inputs, leading to increased production costs and a larger environmental footprint.

Traditional saw cutting, for example, tends to leave behind substantial amounts of waste due to the width of the blade and its inability to precisely control the cut. Furthermore, EDM cutting consumes high amounts of electrical energy and generates more heat, leading to inefficiencies and thermal damage to materials. This wasteful process not only reduces the yield of usable materials but also increases the overall cost of production and energy consumption.

How Diamond Wire Cutting Machines Address These Challenges

Our diamond wire cutting equipment is designed with efficiency and sustainability in mind. Here’s how our technology stands out in reducing waste and contributing to greener manufacturing practices:

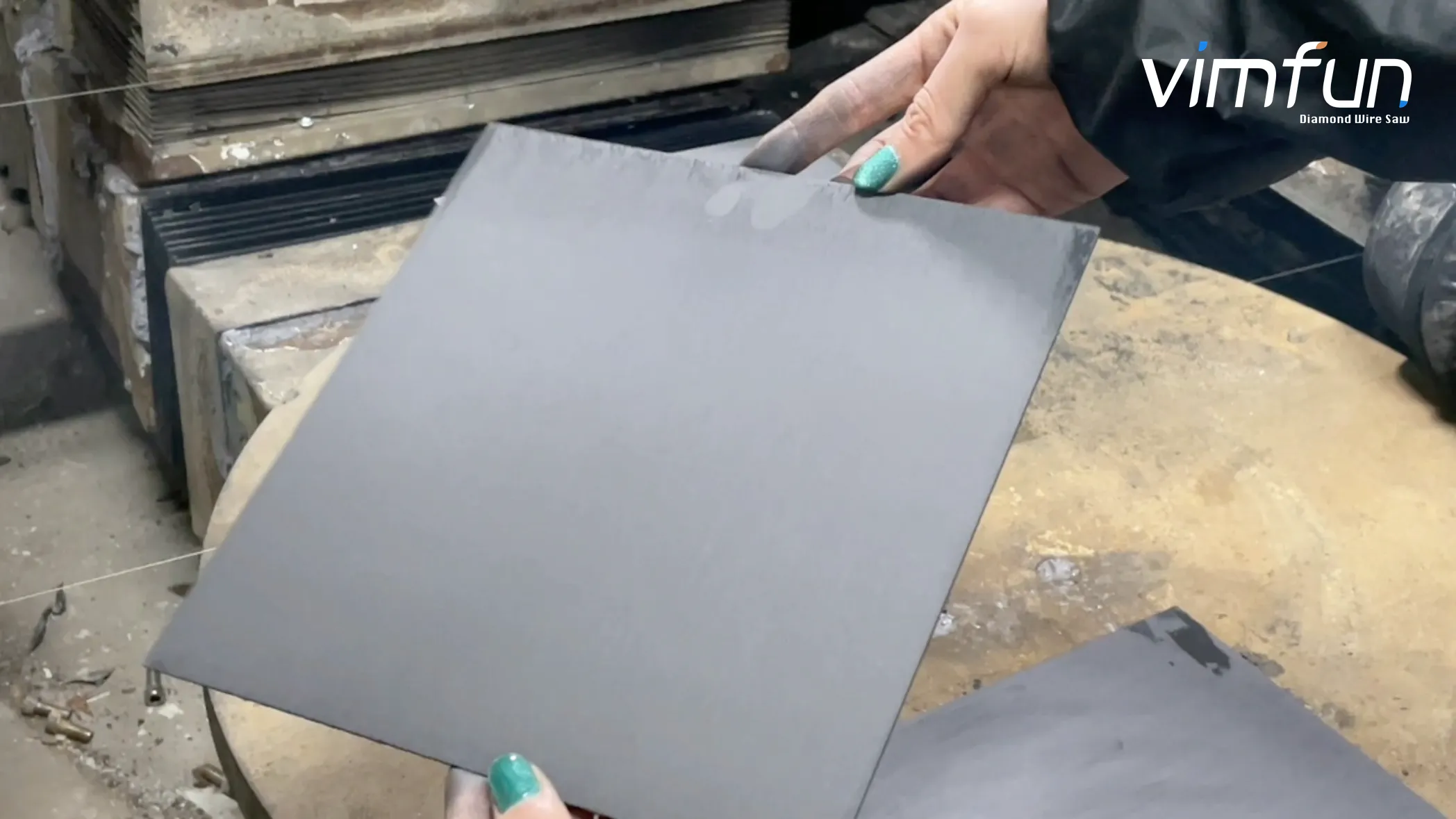

- Minimal Material Waste Unlike traditional saw cutting, diamond wire cutting uses a thin, flexible wire that can be precisely controlled, minimizing kerf (the width of the cut) and significantly reducing material waste. This high-precision cutting method ensures that more of the original material can be used in the final product, reducing waste and improving yield.

- Keywords: Diamond wire cutting, material waste reduction, thin kerf cutting

- Energy EfficiencyDiamond wire cutting saws are designed to operate with lower energy consumption compared to traditional methods. The cutting process is faster, and the need for external cooling or lubrication is minimized, which lowers the energy required to maintain the system.

- Keywords: Energy-efficient cutting, low-energy cutting, reduced energy consumption

- Longer Equipment Life The longevity of diamond wire, especially compared to saw blades, further reduces waste. With longer tool life, there is a reduction in the frequency of replacements, maintenance, and disposal of worn-out parts. This means less waste generated by the cutting equipment itself, contributing to a longer-lasting, more sustainable manufacturing process.

- Keywords: Longer tool life, durable diamond wire, cost-effective cutting

- Reduction of Environmental Impact Our cutting technology also reduces the need for chemicals or other harsh cleaning agents, which are often required in traditional cutting processes like EDM. Since diamond wire cutting saws operate with water-based solutions and produce minimal heat, they not only reduce material waste but also lower the environmental impact associated with industrial cutting processes.

- Keywords: Eco-friendly cutting, sustainable manufacturing, low-emission cutting

Customer Case: Reducing Material Waste in Optical Glass Production

One of our customers, a major optical glass manufacturer, faced significant challenges with material waste and energy consumption in their production process. Prior to using our diamond wire cutting equipment, they used traditional saw cutting techniques, which produced excessive waste when cutting optical glass—one of the hardest and most expensive materials to process. This waste led to higher material costs, more frequent equipment replacements, and greater environmental impact.

After implementing our diamond wire cutting machines, the customer saw the following improvements:

- Waste reduction by 45%: The precision of diamond wire cutting drastically minimized the material lost during the cutting process, allowing the company to use more of the raw material, reducing waste and improving material efficiency.

- Energy consumption reduced by 30%: The customer reported a significant decrease in overall energy use due to the faster cutting speeds and reduced need for additional cooling during the cutting process.

- Lower environmental footprint: With fewer consumables required and less heat generated, the company noticed a substantial reduction in emissions and waste production, contributing to their sustainability goals.

Why Sustainable Manufacturing Matters

Sustainable manufacturing is no longer just a trend—it’s an essential practice for businesses that want to remain competitive in a rapidly changing market. Companies that prioritize environmental responsibility not only help protect the planet but also benefit from improved efficiency, reduced costs, and better customer perception.

Our diamond wire cutting technology aligns perfectly with these sustainability goals by offering an eco-friendly, cost-effective solution that enhances operational efficiency while reducing waste. Whether you’re cutting optical materials, semiconductor wafers, or ceramics, our equipment helps you achieve both your business and environmental objectives.

Conclusion: Achieving Green Manufacturing with Diamond Wire Cutting

As industries continue to strive for greener manufacturing practices, it’s crucial to adopt technologies that reduce waste, conserve energy, and promote sustainability. Our diamond wire cutting saws provide the perfect solution, offering high precision, minimal waste, and energy efficiency, all while maintaining superior cutting performance.

By choosing VIMFUN’s diamond wire cutting equipment, you not only improve the precision and efficiency of your cutting operations but also contribute to a more sustainable and cost-effective manufacturing process. If you’re ready to take the next step toward a more eco-friendly future, contact us today to learn how our technology can help your business achieve its sustainability goals.